Reference News Network reported on October 8, Japanese media said that the global demand for industrial robots was driven by China. According to the International Federation of Robotics (IFR), Chinese sales in 2017 increased by 58%, setting a record of 138,000 units and accounting for more than 30% of the world. The labor shortage and the support policies of the Chinese government have played a catalytic role. China is setting off an unprecedented robot boom.

According to the report on October 8th by the Nihon Keizai Shimbun, according to the survey by Factory Network Asia, the total market share of Chinese local robot companies such as Shanghai Xinshida Robot (STEP) that owns ADTECH is 31.7% as of 2017. Compared with only 26.2% in 2013, it has continued to rise slightly. However, the report also pointed out that in the field of industrial robots in the world, Japanese FANUC and Yaskawa Electric, Swiss ABB and the German KUKA acquired by China Midea Group is considered the world's top four. In China, overseas companies account for nearly 70% of the remaining. In the field of smart phones and home appliances, Chinese companies have surpassed Japanese companies in a short period of time, but there are still gaps in the field of robotics, including technical strength.

According to the report, in China, which is the largest market for industrial robots, local companies are gradually gaining strength. In related fields, the market share of local Chinese companies has exceeded 30% in 2017 and is slowly catching up with Japanese and European companies. What is the Chinese position as the "world's factory" in the field of robotics that influences international competitiveness of the manufacturing sector. "Japan Economic News" interviewed the heads of the two robot companies in Guangdong, China, and asked about the issues and prospects of Chinanese industrial production.

Through electronics factory tempering technology

Adtech is the largest manufacturer of horizontal multi-joint robots (SCARA Robots) for electronic product assembly. Mr. Zeng Yiqiang, chairman of the company, pointed out that if you accumulate experience in electronic products factories such as personal computers, it is possible to catch up with Japan and Europe.

Reporter: In the field of robotics, Japanese and European companies are leading. What do you think for this?

Mr. Zeng Yiqiang: In terms of the durability of SCARA robots, ADTECH is temporarily behind Japanese companies such as Yamaha Engine and Seiko Epson. What we are better at is the ability to respond to meticulous needs. We have a dedicated team dedicated to tightening screws and welding processes and can be dispatched to our customers' factories. No overseas company can deal with it in such detail.

Reporter: How to narrow the quality gap with Japanese and European products?

Mr. Zeng Yiqiang: From the historical point of view, the overseas robot industry generally improves its strength by keeping pace with the country's automobile industry. Nowadays, the demand for electronic products factories such as personal computers and smart phones has also become the driving force for the development of the robot industry.

The electronics factory is concentrated in China. Companies like ADTECH can beat overseas companies if they can meet new demands and focus on R&D.

Labor costs rise to boost automation demand

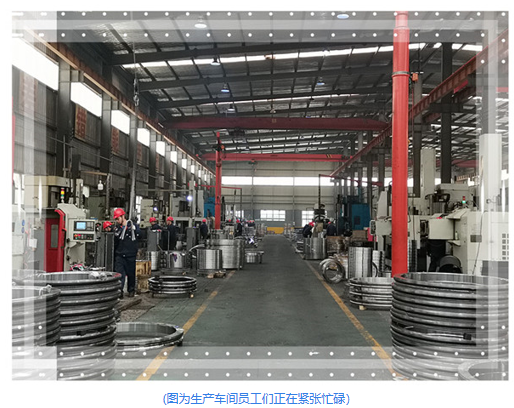

The head of a company responsible for the development of robots in Dongguan pointed out that in order to cope with the increase in labor costs, the automation of the factory is indispensable.

Reporter: How many robots is running in the company?

Responsible person: There are 300~400 units, which will increase to 1000 units during the year. In order to use in the company factory, we started to develop robots in 2013 and started production and introduction in 2015.

Reporter: What is the reason for accelerating R&D and introduction of robots?

Responsible person: Because factories are hard to recruit workers, and labor costs are rising. The current labor costs have almost doubled than the costs in 2008. The number of employees is about 10,000, but when the delivery time of the circuit board of the new smartphone is approaching, there will be a shortage of about 3,000 people. These need to be offset by robot-based automation.

tobmachine